I am searching for a 2017-2018 BMW i3 REx but I have a big concern about charging/driving the car in the dead of winter here in SE Minnesota. We live off-Grid, so using limited home battery power to do preconditioning of the car batteries may be limited at times. Does the REx system fire up and start to warm a cold pack? Can you simply start driving even on a cold pack and manually initiate the REx to warm the pack? Even driving somewhere when it's extremely cold could be a concern if the vehicle is parked for some time and has to be cold-started again a few hours later in a spot with no charging/preconditioning capability. Anyone out there have experience with this?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Does the REx engine heat a cold battery?

- Thread starter BobDowser

- Start date

Help Support BMW i3 Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

No - the design of the Rex version is such that the engine is only intended to run intermittently, and only when the charge state of the battery makes it necessary. So all of the waste heat from the engine remains unused - it is not used to heat the interior, and it is not used to heat the battery.

frictioncircle

Well-known member

Hello BobDowser, welcome to the board!

To add on to mojo's post, the i3 will only precondition (pre-heat) the traction battery if it's plugged in to a power source AND has a departure time set.

You don't mention how many miles you need to cover with your potential i3.

Where I live, winter lows dip into the 40ºs and it definitely shortens the car's range. My initial thought is that an i3 (even with a REx) isn't the best car for a deep-winter state like Minnesota unless your projected mileage is under 50 miles per day.

To add on to mojo's post, the i3 will only precondition (pre-heat) the traction battery if it's plugged in to a power source AND has a departure time set.

You don't mention how many miles you need to cover with your potential i3.

Where I live, winter lows dip into the 40ºs and it definitely shortens the car's range. My initial thought is that an i3 (even with a REx) isn't the best car for a deep-winter state like Minnesota unless your projected mileage is under 50 miles per day.

A trip to town and back in mid-Winter would typically be around 30 miles in total. I'm more concerned about cold weather "lithium plating" on one of the elctrodes more than I am about Winter range. I've read previously that the i3 uses the A/C system to both heat and cool the battery pack. So the REx just supplies electrical power to the wheel motor, not the A/C? If this is true I may give up my i3 search.

- Joined

- Nov 3, 2020

- Messages

- 325

BobDowser said:So the REx just supplies electrical power to the wheel motor, not the A/C? If this is true I may give up my i3 search.

No. That would be a PARALLEL HYBRID like a Prius. This is a SERIES HYBRID. The REX only maintains the state of charge of the HV Battery pack. It has no direct connection to the motor. The HV Battery pack is heated during Pre-Conditioning by resistive wiring that is installed in the battery pack if I recall correctly.

alohart

Well-known member

That's correct. The A/C compressor plumbed as a heat pump (BEV only, not REx) doesn't heat the battery pack, only the cabin.EvanstonI3 said:The HV Battery pack is heated during Pre-Conditioning by resistive wiring that is installed in the battery pack if I recall correctly.

That said, a long-time Norwegian i3 BEV owner claims that the A/C circuit does heat the battery pack in addition to the electric resistance elements, but no A/C system diagram shows a condenser in the battery pack, so I don't understand how that would be possible. Living in the tropics, I have no experience with battery pack heating, so I cannot dispute his claim using real-life experience.

It seems that there are disparate opinions about the construction and wiring of the i3. For instance, only the BEV version has heat pump capability? Does anyone have an overall wiring diagram of the i3 REx? If I can't figure this out I may just have to stick with my gas guzzling (55-75 mpg) 2001 Honda Insight hybrid. Its NiMH battery pack seems to do fine at sunzero temps.

- Joined

- Nov 3, 2020

- Messages

- 325

BobDowser said:only the BEV version has heat pump capability?

There is no room with the REX because the fuel tank and engine take up all the extra space.

alohart

Well-known member

The BMS protects an i3's battery pack by limiting its input and output current when the pack temperature is either very low or very high. This reduces the propulsive power until the cells are warmed by discharging while driving, using the high-voltage cabin resistance heater, etc. Except for some 60 Ah i3 battery packs, significant battery pack problems haven't been common.BobDowser said:I'm more concerned about cold weather "lithium plating" on one of the elctrodes more than I am about Winter range.

If your Insight battery pack is working fine, you must be using a 3rd-party battery cell balancer to equalize the charge levels of all cells at a full charge. Because the Insight's BMS did not implement effective (any?) cell charge level balancing, Honda replaced the battery pack in our 2000 Insight twice under warranty when cell charge level imbalance became so great that the battery pack capacity was reduced below a usable limit. There was nothing that Honda could do about this but replace the battery pack. I began using a 3rd-party battery cell balancer regularly soon after Honda installed the 3rd battery pack which was still going strong when I sold our Insight 10 years later. You would not have this problem with an i3 whose BMS implements passive cell balancing with each of 96 cells monitored. The Insight BMS monitors only groups of 12 cells which could allow a cell to be overcharged or overdischarged which isn't possible in an i3.

The battery pack, BMS, and electronic control modules have improved so much in the 13 years between when the Insight and i3 were introduced that the i3 battery pack should be the least of your worries. However, cold weather behavior is a valid concern. With the 94 Ah battery pack of a 2017 or 2018 i3, you should have sufficient range on the coldest of days with not having to worry about battery cell damage in cold weather.

To learn more about i3, I suggest downloading the various BMW i3 Training Manuals. Several different formats could be downloaded, but downloading just the PDF versions is probably the most usable.

Yes, I have been keeping the Insight's cells equalized using an external charging source, making it nearly a plug-in hybrid. But I plug into a set of nine series-wired, 5 -watt PV panels. That provides about 180 volts at half an amp, just enough to trickle-charge all 120 cells into slight overcharge. Any heat generated by cells that reached capacity before the others is carried off by the onboard 12-volt battery fan.

Thank you for the link to the technical papers! These should answer most of my questions now and in the future. I have beeen reconditioning and replacing Insight battery packs for myself and friends for the past 6 years, and dealing with the quirks of multiple linked computers has become second nature, despite my old-school vehicular training at age 70.

Thank you for the link to the technical papers! These should answer most of my questions now and in the future. I have beeen reconditioning and replacing Insight battery packs for myself and friends for the past 6 years, and dealing with the quirks of multiple linked computers has become second nature, despite my old-school vehicular training at age 70.

alohart

Well-known member

With an i3, you could move on to something other than reconditioning and replacing battery packs because 94 Ah and 120 Ah i3 battery packs have been extremely trouble-free and resistant to degradation.BobDowser said:Thank you for the link to the technical papers! These should answer most of my questions now and in the future. I have beeen reconditioning and replacing Insight battery packs for myself and friends for the past 6 years, and dealing with the quirks of multiple linked computers has become second nature, despite my old-school vehicular training at age 70.

Several Insight owners successfully decoded the data packets on the Insight's data busses which allowed them to do all sorts of things. Our Insight had Mike Dabrowski's early plug-and-play MIMA which intercepts and modifies data bus packets to create custom behaviors and his expensive battery cell balancer that was capable of much more than is probably necessary to balance battery cell charge levels safely. It had Peter Perkins' OBDIIC&C gauge that read data packets and displayed all sorts of information as well as being able to read and delete DTC's. I'm not aware of anyone who has done anything similar with the i3, unfortunately. The i3's data packets might be encrypted or there's just so much data on the data busses that decoding it would be very difficult.

The i3 is far more complex than the Insight. Fortunately, it has been very reliable. We bought a 2014 i3 BEV new which we replaced by a used 2019 i3 BEV about 18 months ago because degradation of the 2014's 60 Ah battery cells had resulted in insufficient range to drive where we wanted without stopping to charge en route. With double the battery pack capacity, our 2019 solved this problem. In 9 years of i3 ownership, there have been no unexpected repairs other than 1 NHTSA recall to reprogram the driver's airbag and 2 BMW service actions to replace an electronic module and a motor mount bracket bolt that could fail.

I consider the i3 to be designed with a philosophy similar to that of the Insight. The Insight was designed to be as light as possible by using aluminum rather than steel for the body, chassis, suspension parts, etc. Likewise, the i3 uses aluminum for its frame, suspension parts, battery pack compartment, etc., carbon fiber reinforced polymer (CFRP) for its passenger cell, and thermoplastic for its exterior body panels. The engineers who designed the Insight and i3 were allowed to use their imaginations to build the most efficient vehicles possible.

Exacly why both the Insight and i3 are no longer produced. Too much in research and production costs.

Our Insight has the MIMA/PIMA system onboard, although for short trips it's not of much use. I found what I was looking for in the PDF tech papaer on heating and cooling systems. Two heat pumps in the BEV versus only one (for the battery pack) in the.REx. Now the disparate mileage figures I had seen for BEV versus REx make some sense, especially in colder weather. I had thought it was due to just the extra weight of an engine and fuel. If I can't get the pack heated up except by plugging in, or depemding on the slight heating of internal battery resistance during driving, perhaps the extra range of the 120AHr BEV pack, and up to 10% extra range from heat pump cabin heat, make more sense overall. There was no mention of anything other than resistance heating for cold weather use in the battery pack for either the BEV or REX versions, but I may have missed something. Being able to utilize the battery pack heat pump would surely be nice to reduce the load on my off-Grid home battery bank during cold weather preconditioning.

Our Insight has the MIMA/PIMA system onboard, although for short trips it's not of much use. I found what I was looking for in the PDF tech papaer on heating and cooling systems. Two heat pumps in the BEV versus only one (for the battery pack) in the.REx. Now the disparate mileage figures I had seen for BEV versus REx make some sense, especially in colder weather. I had thought it was due to just the extra weight of an engine and fuel. If I can't get the pack heated up except by plugging in, or depemding on the slight heating of internal battery resistance during driving, perhaps the extra range of the 120AHr BEV pack, and up to 10% extra range from heat pump cabin heat, make more sense overall. There was no mention of anything other than resistance heating for cold weather use in the battery pack for either the BEV or REX versions, but I may have missed something. Being able to utilize the battery pack heat pump would surely be nice to reduce the load on my off-Grid home battery bank during cold weather preconditioning.

alohart

Well-known member

I used MIMA extensively while driving ~30k miles on European highways. I probably shortened the lives of the battery cells by working them so hard that their temperature climbed as high as 50º C during warm highway driving. The battery pack cooling fan was insufficient for controlling battery cell temperatures during heavy MIMA use. I turned off MIMA when the battery temperature reached 50º C and left the ignition on so the cooling fan remained on while stopping for gasoline, food, whatever. Oh, well, I averaged 62 mpg over 40k miles including some 80 mph driving on European highways which was too fast for much lean burn operation.BobDowser said:Our Insight has the MIMA/PIMA system onboard, although for short trips it's not of much use.

A refrigerant compressor, evaporator, and condenser could be considered to be a heat pump even when the evaporator is cooling the battery pack and/or cabin, so maybe you're counting cooling mode as one heat pump and heating mode as a second heat pump. There's only one set of heat pump plumbing in a BEV with the heat pump option (standard on early U.S. BEV's but optional on later BEV's) and no heat pump plumbing on any Rex. This plumbing reverses the refrigerant flow so that a condenser in cooling mode becomes an evaporator in heating mode and an evaporator in cooling mode becomes a condenser in heating mode. What's especially cool about the i3's heat pump design is that the battery pack can be cooled at the same time that the cabin is being heated, so both heating and cooling modes can operate simultaneously. The diagrams on pp.44-48 in the I01 Heating and A/C Systems Training Manual show these operational modes quite clearly.BobDowser said:Two heat pumps in the BEV versus only one (for the battery pack) in the.REx. Now the disparate mileage figures I had seen for BEV versus REx make some sense, especially in colder weather.

The REx's additional 300 lb. of weight does reduce its range a bit compared with a BEV, but more efficient winter heating might have a larger impact. Note that heat pump heating becomes less efficient as ambient temperatures decrease. Below 14º F, a balmy Minnesota winter dayBobDowser said:I had thought it was due to just the extra weight of an engine and fuel.

If you can find a 2019 i3 BEV with the options that you want, it would seem to meet your needs without the additional complexity, weight, and unreliability of a REx.BobDowser said:If I can't get the pack heated up except by plugging in, or depemding on the slight heating of internal battery resistance during driving, perhaps the extra range of the 120AHr BEV pack, and up to 10% extra range from heat pump cabin heat, make more sense overall.

That's what I have read as well. I don't know whether starting an i3 in advance of departing when the ambient temperature is very low would allow the battery pack heating elements to increase the battery cell temperature enough to increase the driving efficiency enough to offset the energy provided by the battery pack to heat itself. This probably depends on how long the drive is, the ambient temperature, etc. The battery pack is quite dense and requires quite a bit of energy to increase its temperature, so it might not make energy consumption sense to consume battery pack energy to heat the battery pack. I believe that battery pack preheating can take 3 hours to increase the battery pack temperature to the 50º battery pack heating shut-off temperature when the ambient temperature is particularly cold. Hopefully, someone with cold weather i3 operation experience will comment.[/quote]BobDowser said:There was no mention of anything other than resistance heating for cold weather use in the battery pack for either the BEV or REX versions, but I may have missed something.

- Joined

- Nov 3, 2020

- Messages

- 325

alohart said:I believe that battery pack preheating can take 3 hours to increase the battery pack temperature to the 50º battery pack heating shut-off temperature when the ambient temperature is particularly cold. Hopefully, someone with cold weather i3 operation experience will comment.

Up TO 3 hours.

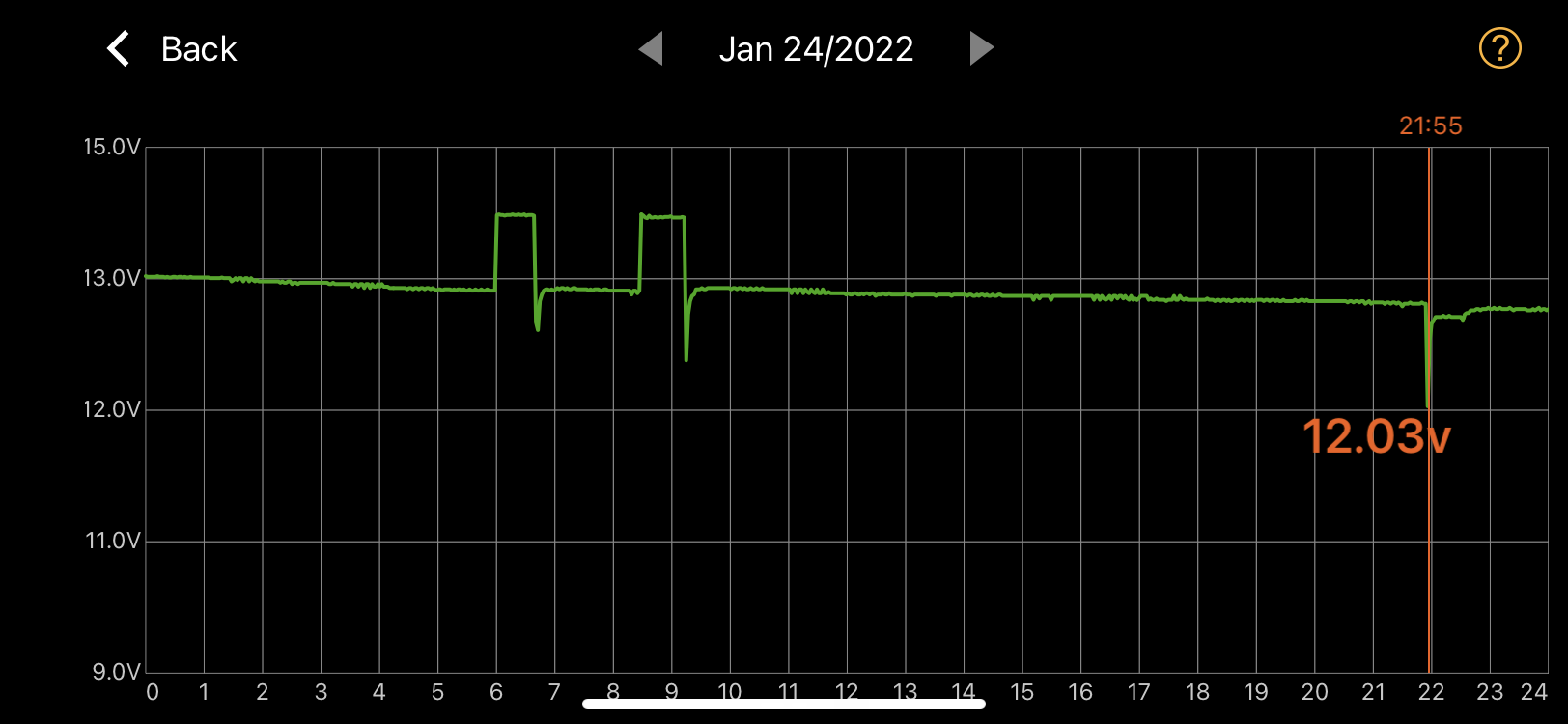

The only anecdotal reference I have available for my BEV, being in Chicagoland, is this snapshot of the car from my Bluetooth 12v battery monitor. This graph shows the car set for a 9am Departure time. Car is in an unheated detached garage and ambient temp IN the garage is about 20F on Jan 24, 2022 (ignore 12.03 v reading on right side)

Note that the first spike is the Pre-Conditioning of the HV battery pack. This comes on for roughly 45 minutes, until the set temp of 50F/10C is reached. Then it shuts off until 30 minutes prior to Departure when the Cabin Heating comes on until 9am. I did not drive the car this day so the Cabin Heating continues for another 10 minutes until it shuts off. I am fairly certain that the HV battery Pre-Conditioning does NOT come on again after reaching the 50F/10C set point as I have checked the battery temp a few times at Departure and it had dropped from 10C to 9C.

At lower temps, the battery pack may indeed need the entire 3 hours to pre-condition but I don't have any data from below 20F for myself.

One last question: Any idea how much wattage travels into the battery resistance heaters, and when the battery is heating will it do so on both level 1 (120-volt) or level 2 (240-volt) charging sources? I've seen the 3 levels that charging can be set for on level 1, so I'm wondering if that can also be configured to minimize wattage during battery heating.

- Joined

- Nov 3, 2020

- Messages

- 325

I know that I can Pre-Condition the HV Battery pack while plugged in to either L1 or L2 at max rate, but the Pre-Condition cycle consumes MORE energy than the L1 charger can provide, so you end up with a few percentage points below a fully charged battery at Departure.

Changing the rates in the car will not affect the Pre-Condition rate as it seems to be fixed. I don't know off hand how many watts it consumes during the process.

Changing the rates in the car will not affect the Pre-Condition rate as it seems to be fixed. I don't know off hand how many watts it consumes during the process.

alohart

Well-known member

I just confirmed that the battery pack preconditioning set point is 10º C (50º F), not 20º C.EvanstonI3 said:Note that the first spike is the Pre-Conditioning of the HV battery pack. This comes on for roughly 45 minutes, until the set temp of 50F/20C is reached. Then it shuts off until 30 minutes prior to Departure when the Cabin Heating comes on until 9am. I did not drive the car this day so the Cabin Heating continues for another 10 minutes until it shuts off. I am fairly certain that the HV battery Pre-Conditioning does NOT come on again after reaching the 50F/20C set point as I have checked the battery temp a few times at Departure and it had dropped from 20C to 19C.

The battery heating elements must consume more than 1.2 kW of power because that's the power output of the AC Level 1 EVSE's included with most i3's. I believe I recall reading that battery pack preconditioning consumed more power than the 1.44 kW AC Level 1 EVSE's included with 2014 and maybe some 2015 i3's.

- Joined

- Nov 3, 2020

- Messages

- 325

thanks for the correction on set point, I updated my comment to reflect your correct values.

alohart said:The battery pack is quite dense and requires quite a bit of energy to increase its temperature, so it might not make energy consumption sense to consume battery pack energy to heat the battery pack.

In my experience, this aspect is tough to understate: the battery is big (even if not by EV standards) and it takes a lot of energy to change the temperature of 500+ lbs of mass. 20 minute trips didn't seem do much to warm the battery when I had to go somewhere without battery preconditioning first and the trip was entirely done on reduced power.

BobDowser said:One last question: Any idea how much wattage travels into the battery resistance heaters, and when the battery is heating will it do so on both level 1 (120-volt) or level 2 (240-volt) charging sources? I've seen the 3 levels that charging can be set for on level 1, so I'm wondering if that can also be configured to minimize wattage during battery heating.

I think 1.3kW is probably about accurate. This screenshot is from a charge session years ago where the surrounding two days had a high of 16F (-9C) and a low of -6F (-21C).

- The rectangle from 4:45 to 6:30ish is resistive battery heating based on a planned departure time of 8:30am.

- The mountain on the right is cabin climatisation, which didn't get a chance to complete before I unplugged

- The left side should be a smooth curve but the spikes are likely battery conditioning. Additionally, from 5:45 to 6:30 it looks like the draw is elevated from where the curve should be, so I think this is likely battery conditioning as well. (I've definitely seen this happen on the chart in the summer when I could hear the cooling running-- otherwise the ramp down curve is extremely smooth.)

You might also find this thread interesting:

https://www.mybmwi3.com/forum/viewtopic.php?p=72522#p72522

But the TLDR is: if the range suits your need, buy an i3 and don't worry about the cold; they can handle it!

Similar threads

- Replies

- 8

- Views

- 2K

- Replies

- 10

- Views

- 3K

- Replies

- 1

- Views

- 600

- Replies

- 27

- Views

- 8K